So also kurzer Zwischenstand. Pauldaytona hat sich bei mir sehr schnell gemeldet

Er hat erstmal geschrieben das sich das Problem normalerweise mit dem gängig machen der Klappe und einer Selbstjustierung und 0 Stellung anfahren lösen lassen sollte.

Hier mal der offizielle Service Bericht bei P1501:

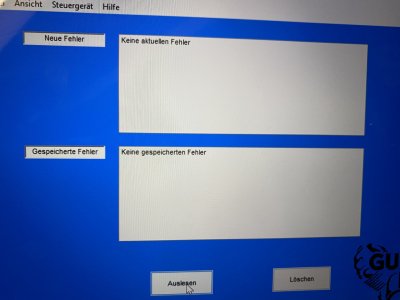

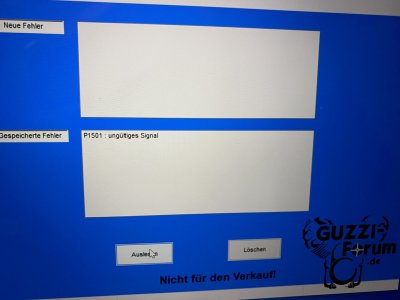

DIAGNOSTIC TOOL: ELECTRICAL ERRORS

P1501 Exhaust valve stoppers search

Diagnosis:

· potentiometer signal above the maximum threshold/ potentiometer signal under the minimum

threshold/excessive duration/search not performed.

Error cause:

If the potentiometer signal is above the maximum threshold: a voltage of the maximum limit

stop (open valve) was detected outside the established range.

· If the potentiometer signal is under the minimum threshold: a voltage of the minimum limit

stop (closed valve) was detected outside the established range.

· If excessive duration: an excessive duration for the stopper search (potential mechanical

problem of he valve, of the motor or cables not connected) was detected.

· If research not performed: this symptom may be caused is a new instrument panel is fitted

and the stopper self-learning has not been yet performed, if the stroke between minimum

and maximum is too short or too long.

This error is indicated by lighting up in a fixed manner the general warning light.

Troubleshooting:

If the potentiometer signal is above the maximum threshold: during the "Exhaust valve selflearning"

setting, a maximum opening limit stop voltage was detected outside the established

range. Check the correct voltage of the two cables of the valve.

· If the potentiometer signal is under the minimum threshold: during the "Exhaust valve selflearning"

setting, a minimum opening limit stop voltage was detected outside the established

range. Check the correct voltage of the two cables of the valve.

· If excessive duration: check if the valve cables are energised: if they are not energised,

energise them; if ok, check if the mechanical rotation of the exhaust valve occur without

friction or delays: if not ok, restore the normal valve rotation; if ok, check the electrical characteristics

of the motor: if not ok, replace the motor; if ok, perform the check procedure for

the valve connector and for the instrument panel connector (with special attention to any

signs of oxidation): if not ok restore; if ok, replace the electric motor. Also check the state of

the cables.

· If research not performed or incorrect stroke: perform the "Exhaust valve self-learning" procedure

if the stoppers learning has not yet been performed after the installation of the new

instrument panel. If the instrument panel is not new, check if the calibration of the cable is

correct and if it is correct, check that there is no obstacle to the valve rotation.

Ich werd jetzt mal die verschiedene Optionen am WE durchprobieren. Zumindest scheint es aber kein allgemeines Problem mit IAWDiag zu geben, sonst würden wir wahrscheinlich auch mehr von dem Thema finden können und er hätte dazu vermutlich auch was gesagt.

Wenn es wirklich der Zufall so will haben wir Beide es tatsächlich geschafft zeitgleich den gleichen Fehler zu erzeugen und dabei halt auch noch mit dem Tool rumgefummelt.